Turbo Troubleshooting & Damage Analysis

If you think your vehicle might have a turbo-related problem, stop before you replace because turbo damage can often be a symptom of an underlying problem rather than the cause itself.

If there is no obvious cause, make sure your turbo specialist completes an extensive troubleshooting program.

The causes of turbo damage usually fall into the following four categories:

1. FOREIGN OBJECTS

Turbo wheel and/or variable vane damage, caused by small objects entering the turbine or compressor housing at high speed, leading to vane movement restriction and wheel imbalance.

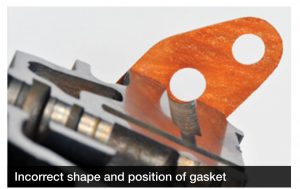

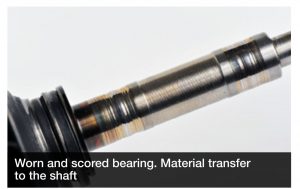

2. LACK OF LUBRICATION

Turbo fatigue cracking and material transfer created by metal to metal friction and high temperatures as a result of oil inlet supply restrictions, incorrect gasket placement and use of liquid gaskets or poor quality lubricants.

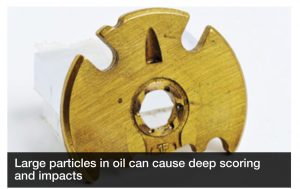

3. OIL CONTAMINATION

Turbo bearing system damage commonly caused by a high concentration of carbon suspended in oil, created by extended oil & filter change intervals or poor maintenance. Bearing damage may also be caused by metallic particles from engine wear or by steel shot suspended in oil following a major engine overhaul.

4. OVERSPEED AND EXCESSIVE TEMPERATURE

Turbo damage caused by working beyond its designed parameters or outside the vehicle manufacturer’s specification. Maintenance problems, engine malfunction or unauthorized performance upgrades can push turbo rotating speeds beyond its operating limits, causing fatigue failure of compressor and turbine wheels.